High Quality Components

The use of high-quality electrical components in electric forklifts brings many benefits, significantly improving overall performance, reliability and cost effectiveness. These high-quality electrical components play a vital role in the efficient operation of the forklift's power system, control electronics and auxiliary equipment, ultimately contributing to a safer and more efficient working environment. High-quality electrical components, such as motors, controllers and inverters, are precisely designed to ensure seamless power conversion and distribution with minimal energy loss. Improved reliability and durability: High-quality electronic components are typically made of advanced materials with robust construction, advanced insulation and corrosion resistant coatings. Designed to withstand the rigors of continuous industrial use, these components are resistant to temperature fluctuations, electrical stresses and environmental factors, thereby extending service life and reducing premature failure.

Cab benefits

The inclusion of a well-designed cabin or enclosed driver's compartment in electric forklifts brings a host of conveniences and benefits that significantly enhance operator comfort, safety, and overall productivity. Here are some key advantages:1. Protection from Environmental Elements: A sturdy, weatherproof cabin shields operators from rain, wind, dust, cold, and heat, ensuring they can work comfortably and efficiently in various indoor and outdoor conditions. This is particularly valuable for operations where forklifts are used in open-air yards, warehouses with fluctuating temperatures, or facilities with poor climate control.2. Improved Ergonomics and Operator Comfort: A well-appointed cabin typically incorporates features such as adjustable seats, ergonomic controls, ample legroom, and effective sound insulation, which minimize operator fatigue and strain over long shifts. These enhancements promote a healthier working environment, increasing focus and reducing the risk of musculoskeletal disorders associated with prolonged sitting or repetitive motions.

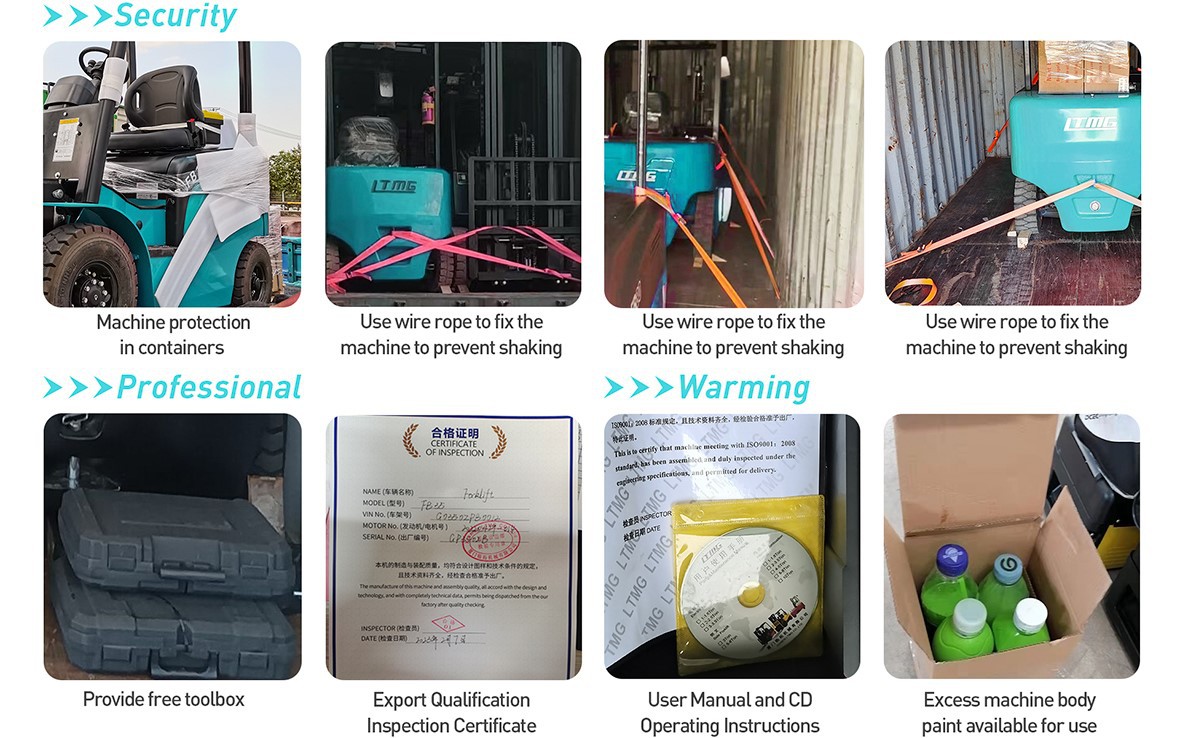

Packing and Loading

During container loading, the use of wire rope to secure the electric forklift is a key step to prevent excessive movement and ensure safe and stable transport of the machine. Properly stretched and anchored when loading, acting as a flexible and sturdy connection between the forklift and the container. It effectively absorbs and dissipates vibration forces generated during transportation, whether due to uneven roads, acceleration, deceleration, or ship movement. This reduces the pressure on the forklift components and minimizes the risk of loose connections, component damage or structural fatigue. Load distribution: By evenly distributing the weight of the forklift across multiple connection points, the wire rope helps maintain load balance within the container. This is especially important when dealing with heavy machinery like electric forklifts, where uneven weight distribution can lead to container instability, resulting in potential damage to the forklift and the container itself.

Hot Tags: electric forklift 5000 lb, China electric forklift 5000 lb manufacturers, Vna Lift Truck, container handling forklift, Diesel Side Loader, Lpg Forklift Truck, Articulating Boom Lift Producer Supplier, telescoping man lift