Closed Cabin

The cabin is equipped with heating, ventilation and air conditioning systems to maintain a consistent and comfortable temperature for the operator, regardless of the outside conditions. This not only improves operator comfort, but also helps maintain alertness and concentration, especially in extreme climates. In addition, air filtration systems can help maintain good air quality in the cabin, protecting operators from air pollutants and allergens. Reduced noise exposure: The enclosed cabin effectively suppresses engine noise, hydraulic hiss and other ambient sounds, creating a quieter working environment that contributes to operator health and reduces the risk of noise-induced hearing loss. Improved acoustics also enable clearer communication between operators and colleagues, improving overall safety and coordination. Lockable doors provide additional security for the operator and the forklift itself, and the cabin often has designated storage compartments for personal protective equipment, tools, or other work necessities, keeping the operator's workspace organized and clean.

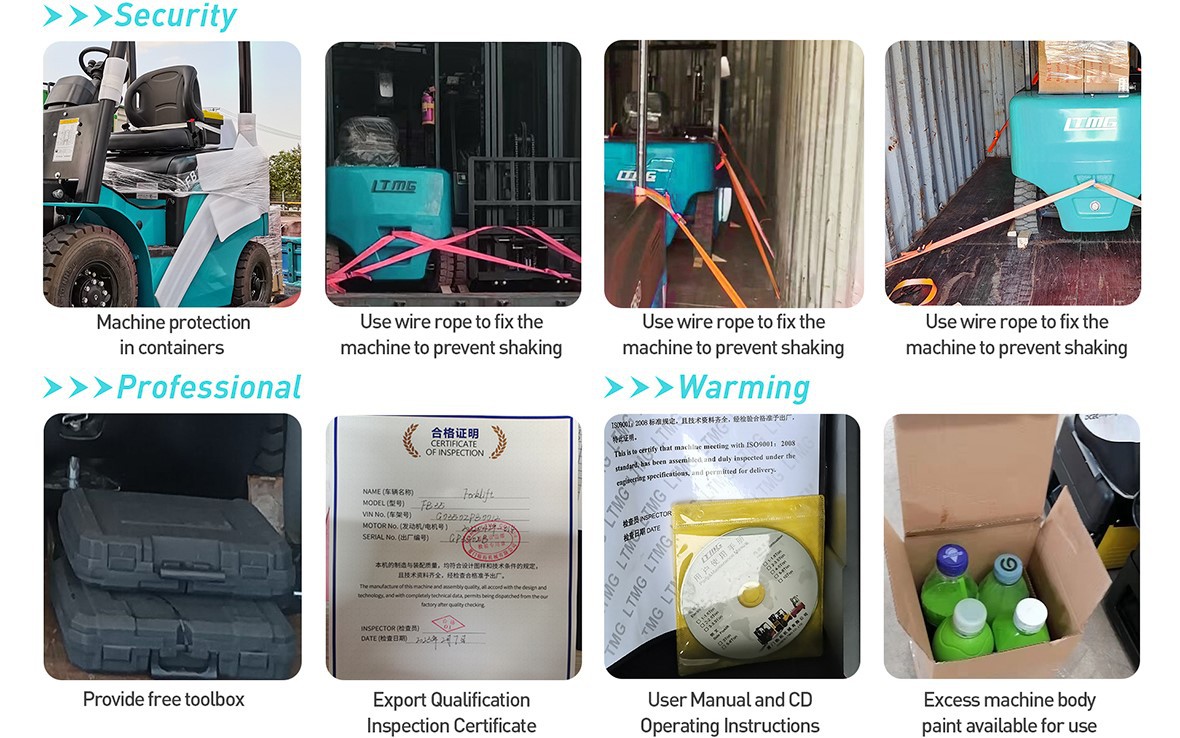

Packing and Loading

Using wire ropes that comply with established lashing guidelines and standards not only protects forklifts, but also reduces legal and insurance risks associated with improper cargo safety. Customizable fit: Wire rope, available in a variety of lengths, diameters and configurations, can be customized to fit the specific size and weight of the electric forklift being transported. This allows for a precise, comfortable fit that optimally restricts the machine without undue stress on sensitive areas or components. In addition, the flexibility of the wire rope allows it to adapt to irregular shapes or bumps on the forklift, ensuring safe retention even in challenging loading scenarios. Reusable and durable: Wire rope is a highly durable and elastic material that can withstand the harsh conditions encountered during transportation, including exposure to moisture, salt and extreme temperatures. Its strength and corrosion resistance make it suitable for reuse, reducing the need for frequent replacement and helping to provide a more cost-effective and environmentally friendly fixed solution.

Electrical Components

High-quality electrical components usually comply with strict industry standards and regulations, ensuring that the electrical system of electric forklifts meets or exceeds safety requirements. Features such as overcurrent protection, short circuit protection and temperature monitoring help prevent electrical hazards and protect operators, bystanders and the forklift itself from potential accidents or damage. Environmental protection and sustainability: Advanced electronic components may also have energy-saving technologies, regenerative braking systems or compatibility with renewable energy sources, helping to reduce carbon footprint and reduce environmental impact. This aligns with sustainable business practices and helps the company achieve its environmental goals. Reduced maintenance and downtime: High-quality electrical components require less frequent maintenance and are less prone to unexpected failures. Longer service intervals, combined with higher reliability, minimize unplanned downtime and keep your fleet of forklifts operational and productive for a long time. This, in turn, reduces maintenance costs and improves overall equipment availability.

Hot Tags: electric forklift 3 tons, China electric forklift 3 tons manufacturers, Ewp Scissor Lift, Articulated Forklift Rough Terrain, 5 Ton Diesel Forklift, warehouse stock picker, container port equipment, very narrow aisle forklift